Description

The IntellX wire feeder is an industrial - grade device. Its new arc control feature allows welders to create high - quality welds with very few parameter adjustments. It's designed to work perfectly with Deltaweld 350 and 500 power sources.

Legacy Meets Pulse

The Deltaweld with Intellx Pro feeder, capable of pulsed MIG, offers a 28% wider operating window and a more forgiving arc. This compensates for differences in operator skills, enabling welders of all levels to start production faster.

Dedicated Wire Feeder

The Intellx feeder's new arc control feature simplifies the welding process, helping you achieve better welds with minimal parameter changes.

Included with Product

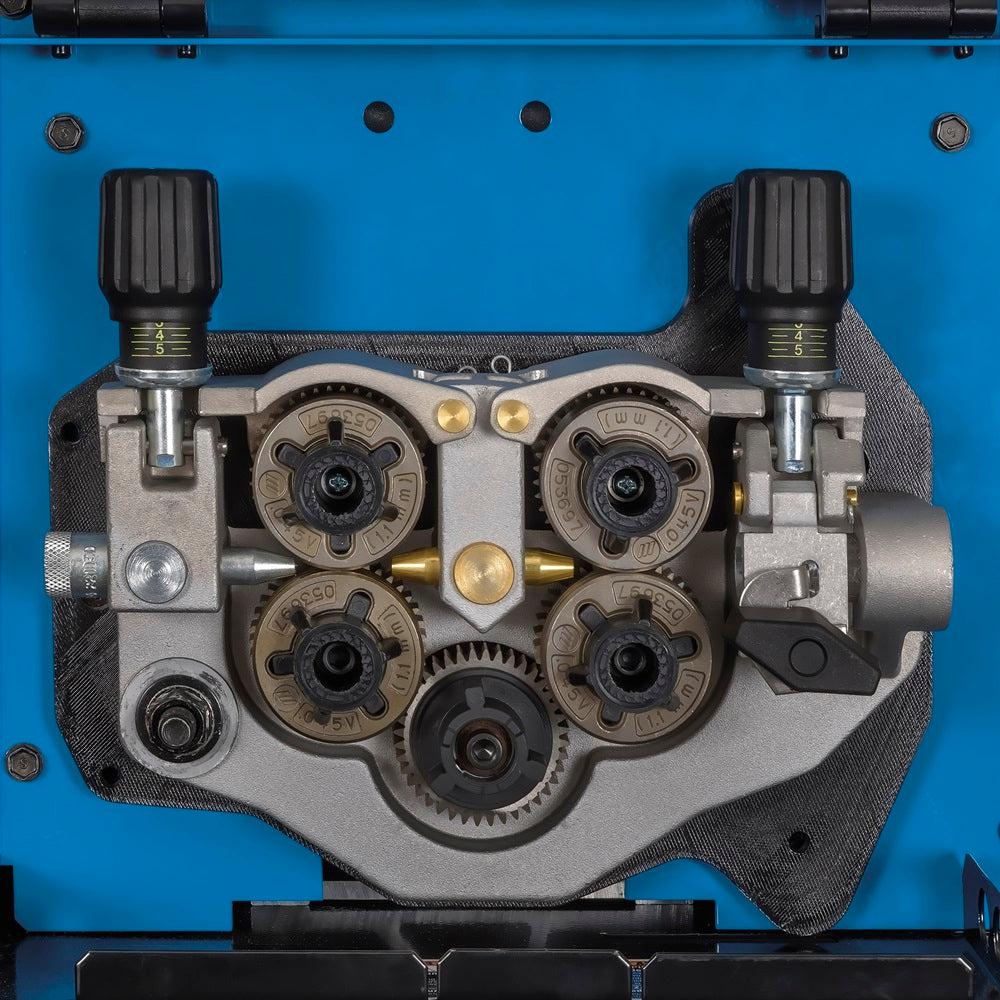

- Intellx Wire Feeder

- Bernard BTB 400 A gun

- .035/.045 in V - groove drive rolls

Specifications

Click to view full Spec Sheet.

Video

Using the Miller IntellX Feeder is quite straightforward. First, make sure it's connected to either a Deltaweld 350 or 500 power source. Once connected, you can start using the Bernard BTB 400 A gun that comes with it. Thanks to the new arc control feature, you don't need to make many adjustments to the parameters to get a great weld. Even if you're new to welding, you can quickly get into production because of the wider operating window and forgiving arc. When it comes to maintenance, keep the feeder clean and check the.035/.045 in V - groove drive rolls regularly for any signs of wear. Always follow the safety instructions in the full spec sheet. If you encounter any issues, refer to the video for additional guidance.