Description

Top Features

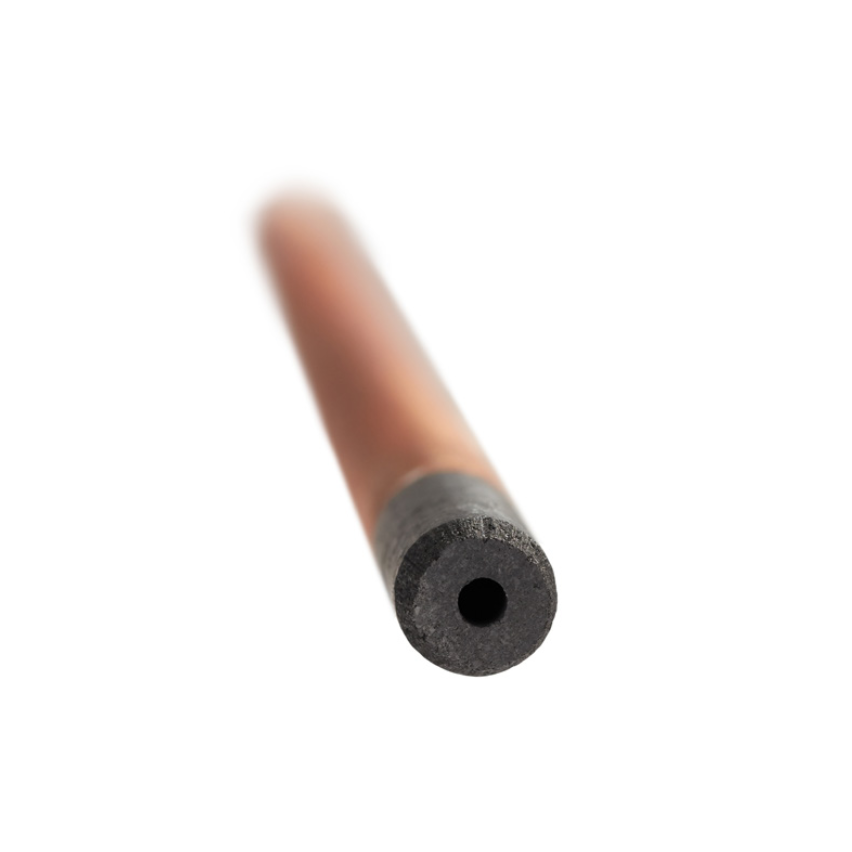

- High - quality synthetic graphite boosts electrode lifespan and maximizes metal removal.

- Completely copper - coated design enhances arc stability and cuts down heat generation.

- Uniform melt - off rate results in smooth, even grooves.

- High - density formula makes the electrodes more durable.

Elite Performance

CarbonElite arc gouging carbon electrodes are crafted from a special composition for super - efficient metal removal. The copper - coated carbons provide outstanding arc stability and less heat, ensuring a well - controlled melt - off rate. They come in pointed, jointed, flat, and hollow types, perfect for many semi - automatic or automatic applications.

Typical Applications

- Get rid of defective welds.

- Remove surface welds for re - surfacing.

- Prepare joints before welding.

- Backgouge base material for full - penetration weld deposits.

Specifications

Click to view the entire spec sheet.

Using these Lincoln CarbonElite Hollow 12 Gouging Electrodes is quite straightforward. First, select the right electrode type (pointed, jointed, flat, or hollow) according to your application. For semi - automatic or automatic operations, make sure your equipment is properly set up. When using, keep in mind that the electrodes are designed to maximize metal removal. Some important things to note: Avoid overheating the electrodes. Although they are copper - coated to reduce heat, excessive heat can still affect performance. Also, ensure a stable arc for the best results. For maintenance, store the electrodes in a dry place. Keep them away from moisture as it can damage the copper coating and the graphite composition. If you notice any signs of wear or damage, it's a good idea to replace the electrode to maintain optimal performance.